English

English

Views: 0 Author: Site Editor Publish Time: 2025-10-07 Origin: Site

As part of continuous material improvement, we compared soft and hard bushings based on real usage feedback and production testing.

Soft bushings are made from flexible rubber that helps absorb minor vibrations and offers a more comfortable feel on uneven surfaces. They are often preferred in general commuting or light-duty motorcycles. However, soft rubber tends to wear faster under high stress or long-term use.

Hard bushings are produced from a firmer compound that resists compression and deformation. They maintain their shape better over time, resulting in greater stability and reduced maintenance. Unlike common assumptions, they do not create additional noise or harshness compared to soft bushings—riders often can't even tell the difference in feel.

What truly changes is durability: these upgraded bushings hold up better under challenging terrain and heavier loads, minimizing the need for replacements.

![]() This improvement naturally leads into one of the most practical benefits — lower long-term cost and fewer maintenance concerns, which we’ll explore in the next section.

This improvement naturally leads into one of the most practical benefits — lower long-term cost and fewer maintenance concerns, which we’ll explore in the next section.

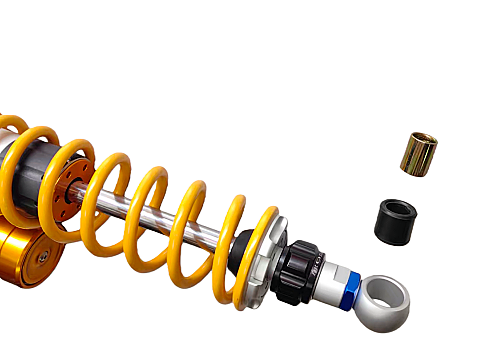

Bushings play a small but important role in how the shock absorber handles vibration, alignment, and long-term stability.

Soft bushings offer slightly better comfort and noise damping, but wear faster under heavy or long-term use.

Hard bushings provide better shape retention and wear resistance, reducing maintenance frequency.

The switch to harder bushings is a durability-focused decision, based on continuous field use and distributor feedback—not marketing hype.

Both materials remain available, as some customers still prefer the softer option for specific riding conditions.

Bushings are small yet essential parts in motorcycle and ATV suspension systems. Positioned between the shock absorber and the vehicle frame, they minimize metal-to-metal contact, helping to reduce vibration and noise. While they don't directly control damping, they support smoother and more stable suspension movement.

Soft bushings are typically made from rubber, offering better comfort and vibration absorption for everyday riding. Hard bushings, in contrast, use a denser, more wear-resistant polymer that provides longer service life and helps maintain structural stability under heavy loads. The difference lies more in durability than in riding feel.

| Bushing Type | Function / Feature |

| Soft Bushing | Made from flexible rubber for better vibration absorption. |

| Hard Bushing | Uses a dense, durable polymer to resist wear and deformation. |

Soft bushings are usually made from flexible rubber, helping absorb small road vibrations and reduce noise for a smoother overall ride. Hard bushings, on the other hand, use denser and more durable compounds that resist wear and deformation, maintaining stability and alignment over longer use.

Unlike metal sleeves that offer stronger rigidity but limited adaptability, rubber and polymer bushings allow easier fitment across different shock eye sizes such as 10 mm, 12 mm, 14mm,or 16mm — one key reason we rarely use fully steel bushings in our designs.

Bushings serve a supporting role in motorcycle and ATV suspension systems. They help reduce vibration at the connection points and allow limited flexibility between components. However, bushing hardness can still influence the overall ride feel — softer bushings deliver more comfort, while harder ones create a firmer and more responsive ride. Soft bushings offer a slightly more forgiving feel, while hard bushings improve fit stability and resistance to wear.

For manufacturers and distributors, choosing between soft and hard bushings mainly affects maintenance convenience and part compatibility. This choice also relates to product standardization—harder bushings can last longer under repeated loads, while softer ones are easier to replace for different eye-to-eye distances.

A balanced understanding of these materials helps businesses match performance needs with practical requirements, ensuring each shock absorber design delivers both consistency and flexibility across various models.

Soft bushings are valued for their ability to provide a smoother and quieter ride. Made primarily of rubber, they isolate small vibrations and minimize noise between suspension components. This makes them suitable for riders who prioritize comfort and a softer suspension response.

In typical motorcycle or ATV designs, rubber bushings reduce vibration transfer, prevent metal-to-metal contact, and help maintain alignment across connecting parts. By doing so, they extend component life and preserve handling consistency over time.

Manufacturers often select soft bushings for lighter vehicles or comfort-oriented models, where vibration damping is more important than extreme rigidity. These bushings allow controlled movement between joints, absorb shocks on uneven terrain, and maintain a balanced feel at moderate speeds.

Soft bushings present a cost-effective solution for OEMs and distributors seeking lower production or replacement costs. The table below compares how soft bushings perform relative to harder alternatives in terms of longevity, cost, and requirements:

Key Differences Between Soft and Hard Bushings:

| Feature / Aspect | Soft Bushing (Rubber) | Hard Bushing (Polyurethane / Reinforced) |

| Ride Comfort | Excellent vibration absorption, smoother feel | Less absorption, may transmit more road feedback |

| Durability | Moderate lifespan; wears faster under heavy loads | Long-lasting; resists deformation and aging |

| Cost | Lower manufacturing and replacement costs | Higher initial cost but longer service interval |

| Performance Focus | Comfort and flexibility for general use | Stability and precision for sport or heavy-duty use |

| Common Issues | Rubber aging, cracks over time | No problems have been found so far, under observation |

Although more affordable, rubber bushings generally have shorter service lives under heavy loads or frequent high-impact use. As they wear, riders may notice increased vibration, noise, or irregular tire wear—common indicators that replacement is needed.

The core function of a rubber bushing is to limit unwanted motion and absorb minor shocks while maintaining the flexibility of the suspension system. For manufacturers and B2B partners, the key lies in balancing the initial cost advantage with the potential need for earlier replacement.

Harder bushing materials, as the next section discusses, provide longer durability and greater stability without significantly compromising comfort.

Hard bushings are more durable than soft ones, mainly because of the tougher materials they use—often polyurethane or other dense compounds. This makes them a practical choice for motorcycles or ATVs that frequently handle rougher terrains or heavier loads.

They resist wear and tearing better during long-term use.

Their firmer texture helps maintain stability under repeated compression.

In some cases, they can withstand stronger impacts with less tendency to show fatigue over time.

![]() Note: While hard bushings offer better wear resistance, they don't significantly change suspension performance or comfort under normal conditions.

Note: While hard bushings offer better wear resistance, they don't significantly change suspension performance or comfort under normal conditions.

With proper installation, hard bushings help distribute forces more evenly across mounting points, reducing local stress and minor deformations.

Overall, they provide a slightly firmer connection between suspension parts—enough to improve durability and consistency over time, but without sacrificing comfort or flexibility in everyday riding.

Hard bushings perform reliably in setups where the suspension must endure heavy stress or frequent load changes. Their reinforced construction allows them to maintain shape and function even when supporting larger vehicles or heavier riders, making them suitable for commercial fleets, off-road use, and performance-oriented motorcycles.

Upgrading to harder bushings can lead to slightly improved stability and handling under demanding conditions.

Hard bushings offer better load-bearing capability, allowing forces to distribute more evenly across the suspension system.

They also tend to resist deformation longer than soft types, which helps maintain consistent geometry during cornering or impact.

However, these advantages come with a practical limitation. Hard bushings are usually designed to fit specific eyelet sizes, making them less adaptable for replacements or different suspension setups.

![]() Note: This fixed-fit design improves durability and precision, but it also means they are harder to interchange if the suspension eye distance varies between models.

Note: This fixed-fit design improves durability and precision, but it also means they are harder to interchange if the suspension eye distance varies between models.

From a business perspective, manufacturers and distributors benefit from reduced replacement frequency and lower long-term maintenance costs. The result is greater durability and value over the product's lifecycle—an advantage that directly affects both customer satisfaction and operational efficiency when compared to softer alternatives.

At RFY SHOCK, we're constantly looking for ways to make our shock absorbers more durable and consistent in real-world use. After years of testing and feedback from distributors and riders, we found that soft bushings—though smooth and comfortable—were not the best fit for the demands of today's riding environments.

![]() Simply put, hard bushings offer better resistance to wear and maintain performance longer under stress.

Simply put, hard bushings offer better resistance to wear and maintain performance longer under stress.

A longer service life means fewer replacements and less downtime, which benefits fleet operators, manufacturers, and distributors. Reliable suspension components also reduce the need for frequent inspections and minimize unexpected part failures.

From an operational standpoint, this extended lifespan supports a more efficient maintenance cycle and lowers total ownership costs — helping businesses deliver dependable products with consistent performance across markets.

Hard bushings offer a longer lifespan with reduced deformation.

Their dense structure helps maintain suspension precision.

Extended durability supports smoother operations and reduced maintenance costs.

This change wasn't about following a trend—it was about improving long-term reliability for our partners and end users. By upgrading to hard bushings, we reduced the frequency of replacements while keeping the same level of comfort and control riders expect from RFYSHOCK products.

From a business perspective, the total lifecycle cost matters more than the initial price. At RFY SHOCK, upgrading from soft to hard bushings does not increase the product cost — distributors and clients can enjoy enhanced durability without higher expenses.

In practical terms:

Hard bushings last longer, reducing replacement frequency and long-term spending.

Lower maintenance needs help businesses save both time and labor.

A consistent cost structure supports predictable margins and smoother supply planning.

A comparison of lifecycle costs highlights the advantages of hard bushings:

| Factor | Soft Bushings | Hard Bushings |

| Initial Cost | Lower | Similar |

| Replacement Frequency | More frequent | Less frequent |

| Maintenance Needs | Higher | Lower |

| Total Cost Over Time | Higher | Lower |

Distributors who supply parts to commercial fleets or performance markets appreciate the reduced replacement demand. This reliability improves customer satisfaction and helps maintain long-term partnerships.

The transition from soft to hard bushings represents a strategic upgrade — delivering better durability, consistent performance, and stable pricing. With this improvement, RFY SHOCK continues to provide dependable suspension solutions designed for value and long-term results.

Across multiple platforms and customer feedback channels, we noticed a clear trend — soft bushings tend to crack or deform more easily, especially when riders explore off-road environments such as forest trails, grassy areas, or uneven terrain. On smoother surfaces, soft bushings perform just fine. But because many riders enjoy diverse riding conditions, durability became a key factor in our decision to upgrade.

To address it, we upgraded our design from soft to hard bushings. The new bushings are more durable and resistant to pressure while maintaining the same smooth riding experience. In fact, most retail customers didn’t even notice the change in feel — only that negative feedback and maintenance reports dropped significantly after the update.

![]() Note: The upgrade doesn’t change how the suspension feels — it simply lasts longer and stays reliable even under tougher conditions.

Note: The upgrade doesn’t change how the suspension feels — it simply lasts longer and stays reliable even under tougher conditions.

After the upgrade, we revisited multiple platforms and customer feedback channels, and we found that comments or complaints regarding the rubber issues have virtually disappeared, indicating a significant improvement in product performance and customer satisfaction.

By improving material durability without affecting comfort, we ensured that riders enjoy the same familiar performance — just with fewer problems down the road.

Switching from soft to hard bushings wasn't just a minor material change — it was part of our ongoing effort to improve product reliability and customer satisfaction. After the upgrade, riders reported fewer complaints about cracking or deformation while enjoying the same comfortable ride feel.

For distributors and OEM partners, this means fewer replacements, steadier quality, and greater confidence in every shipment. As riding environments and market demands continue to evolve, RFY SHOCK remains focused on providing suspension solutions that balance comfort, durability, and long-term performance.

Q: Why did RFYShock switch from soft to hard bushings?

A: We made the switch after reviewing customer feedback across multiple markets. Soft bushings tended to crack or deform when exposed to rough terrain. Hard bushings improve durability and stability while keeping the same comfortable ride feel.

Q: Will the hard bushings make the ride stiffer?

A: Not really. Most riders report that the overall comfort remains consistent. The key difference is that hard bushings handle impact and load more effectively, reducing wear and deformation over time.

Q: Do hard bushings require maintenance?

A: Hard bushings generally don't require maintenance, but checking for wear during routine suspension inspection is always a good practice.

Q: Did the material upgrade increase the cost?

A: No, the switch to hard bushings didn't raise product costs. Distributors and partners benefit from the same pricing while enjoying better durability and product consistency.

Looking to improve your motorcycle's comfort and handling? Explore the RFY SHOCK range of precision-engineered shock absorbers designed for different riding styles

International Trade & Product Development Specialist at RFY SHOCK